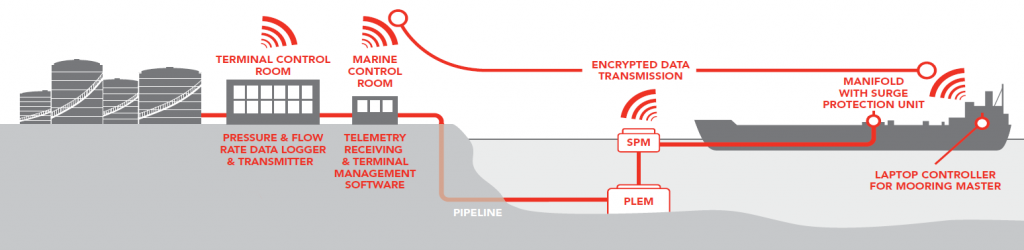

Telemetry System

The Offshore Ops Telemetry System provides operators with an effective tool to operate, manage, maintain and integrity monitor the performance offshore oil transfer systems. The system can provide live meteorological, oceanographic and operational data locally to personnel on site and the Marine Office.

The data allows operations staff to monitor local sea and weather conditions, oil transfer pressures, hawser loads, buoy position, inclination and excursion giving an immediate overview of the status, safety and integrity of the operation. In addition to the live data, all information is stored on a SQL database to build up a historical record of the system operation assisting with maintenance, reporting and incident investigation.

The key factor of the telemetry is to enable the operator to manage the facility and avoid an oil pollution incident resulting in environmental damage and adverse reputational impact.

The telemetry system is specifically designed incorporating the strictest type approval requirements. Increased Explosion proof protection is applied to the design using the buoy zoned area classification.