Terminal Management System

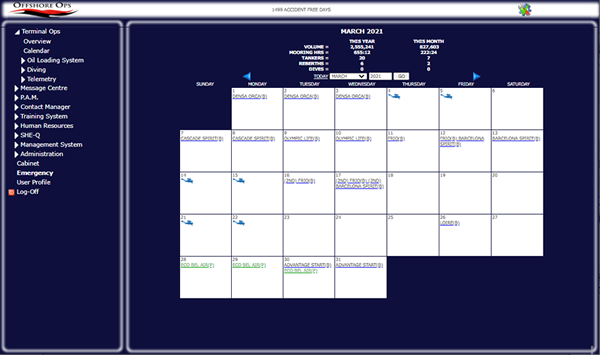

Offshore Ops’ Terminal Management System allows oil terminals to maximise terminal availability and efficiency, increase safety, reduce operating costs and reduce environmental incidents.

Offshore Ops’ fully OCIMF SMOG 2015 compliant Integrated Terminal Management System has been systematically developed over 12 years to provide ‘live’ data on a wide range of operational and environmental factors, as well as effective operations management, significantly reducing risk and enhancing mooring and offloading safety and performance.

Offshore Ops’ Integrated Terminal Management System has been developed based on the needs of single and multi-operator terminals. It comprises an array of sensors on the offloading buoy, together with a portable monitoring unit used by the mooring master on the tanker, providing ‘live’ data on all aspects of offloading operations.